Manufactured products

Production capacity

Electromechizmerenie is a manufacturing enterprise that implements an end-to-end technological cycle. All stages of production from design to packaging are carried out exclusively in our own workshops.

plastic casting workshop

plastic casting workshop one of the lines in the stamping workshop

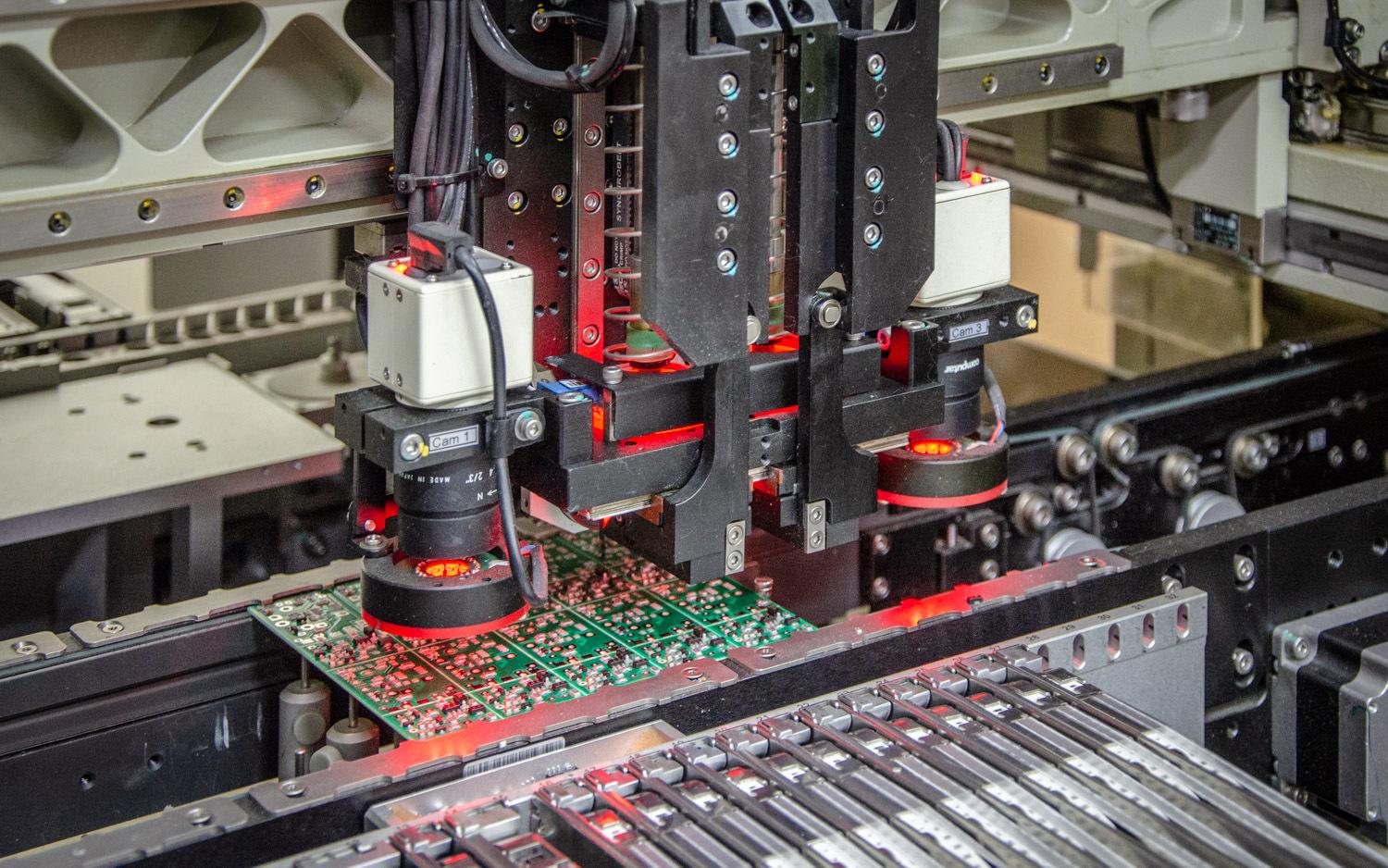

one of the lines in the stamping workshopFactory staff has mastered a large variety of technical processes, including metal working, stamping, cold heading, plastic casting, spring coiling, circuit board assembly and many others. The company’s own tooling workshop provides the production with molds, stamps and rigging, which positively effects the selling price and reduces the risk of downtime. Thanks to many years of investment, all technical processes are carried out on modern equipment (for example, Fehlmann PICOMAX for electrical discharge machining, Po Ly Gim Mini-88 for turning, Siger and KuASY for plastics casting, LUNA ECM700 for surface mounting of circuit board components, YHM EF-210 for spring coiling and so on).

manufacturing of fitting for sensors and switches

manufacturing of fitting for sensors and switches automated spring winding

automated spring windingWe have created a unique school of new product development – both engineering and mass production are orchestrated by the EMI design office. Our engineers not only manage to expand the product catalog by 10-15 items a year, but are also able to perform complex non-standard tasks.

Thus, EMI became the first Russian producer of sensors and switches with a bayonet connector and was also first to supply them to the country’s automotive conveyors. And in 2015, based on an urgent order from the Bryansk Automobile Plant (BAZ), we designed backup light switch 1352.3768-02 in just one day. The entire process of preparing to mass-production, including the manufacturing of the mold, stamps and tooling, took nine days. This switch has been protected by a patent and is currently supplied to hundreds of organizations, including plants such as BAZ, KAMAZ, YMZ, TMZ and ZMT.

assembly and quality control department for automotive relays

assembly and quality control department for automotive relaysWe have been working for over 30 years, so we know how to produce automotive sensors and electronics timely and with high quality. By continuously analyzing the needs of the market, we maintain a range of items at the warehouse of finished products and process most orders in just one to three days.

The experience and technologies allow us to produce non-standard automotive components as well. We quite often discuss such tasks with the businesses and happily solve them. Based on this cooperation, our clients manage to reduce costs by 5-7 times compared with the use of alternatives from abroad. Examples of this savings opportunity are the sensors 6072.3829-01, 6072.3829-05 and 6072.3829-06, which we produce on request.

heavy-duty cold heading machine

heavy-duty cold heading machine one of the SMT pick-and-place machines

one of the SMT pick-and-place machinesCertificates

Our company is compliant with ISO 9001:2015 + IATF 16949:2016, which is a strict quality management system covering the entire product life cycle. This is confirmed by two certificates issued by United Registrar of Systems Ltd.

The products we manufacture have been designed by our own engineering team and are protected by a number of patents. Some of the models in our catalog have no analogs on the market. All mass-produced items meet the requirements in the Technical Regulations of the Customs Union 018/2011 ‘On the safety of wheeled vehicles’.

Clients

At Electromechizmerenie we ship goods to over 800 companies all over Russia and also work directly with clients from Kazakhstan and Belarus.

We are proud to supply products to over thirty manufacturing plants and we think it’s a solid proof of our responsibility and dedication to quality.

UZAMsince 1992

UMZsince 1993

ZILsince 2002

UAZsince 2003

ZMZsince 2004

KAMAZsince 2005

GAZsince 2007

PAZsince 2009

Uralsince 2010

Volgabussince 2012

YaMZsince 2013

BAZsince 2014

MTZsince 2014

PTZsince 2014

BZTDAsince 2015

TMZsince 2015

CDB Turbinasince 2015

ZMTsince 2015

LiAZsince 2016

MMZsince 2016

Rostselmashsince 2016

Tulamashzavodsince 2016

Vityazsince 2016

RMsince 2017

Radiovolnasince 2017

AMZsince 2018

Remdizelsince 2018

SAZsince 2018

ABERsince 2019

MAZsince 2021

Uraltransmashsince 2021

Becoming our new client is easy – simply contact us.

Company history

- 1991

Penza Factory Electromechizmerenie was established by a group of young professionals from NIIFI (a research institute which made sensors for space industry). The first product of our company was an accurate scaling unit with bespoke design; it was dedicated for a system called ‘Vityaz’ that was used to eliminate the consequences of the Chernobyl accident.

- 1992

We began to manufacture oil pressure alarm sensor 6012.3829 (analog for ММ 111 Д) for the Ufa Motor Plant (UZAM). This event has defined automotive components as the main focus of our factory.

- 1993

Our team proceeded to mass-production of new types of sensors and switches; we started supplying products to the Ulyanovsk Motor Plant (UMZ).

- 1996

The manufacturing of voltage regulators began. Our product catalog consisted of nine items.

- 1998

We initiated the production of our first turn signal relay (57.3777) and expanded the catalog by five additional items.

- 2000

Following the construction of a new workshop, we managed to create an end-to-end technological cycle. From this time the machining of fittings and the casting of plastic bodies have taken place within EMI, which has reduced production costs and has given us full control over the quality.

- 2003

Electromechizmerenie was certified with ISO 9001-2001 - this gave our company right to supply products to a greater number of automobile plants.

- 2008

There were 49 items in our catalog by the start of the year. An economic crisis stroke the country and motivated us to optimize the internal processes as well as to revise the company’s strategy. We initiated the production of electromagnetic and starter relays.

- 2009

The number of clients and the volume of manufactured products increased significantly. This gave us resources to launch a large-scale upgrade program for the equipment and also speeded up the development of new products. Starting from this year, our catalog has been annually expanding by 10-15 items.

EMI implemented a strict quality management system GOST R ISO/TS 16949:2009, which further raised our standards of design, development and mass-production.

- 2013

We finished the construction of two new workshops and expanded our production facilities. The introduction of modern technologies at the new site helped reduce manufacturing costs and made it possible for us to ship high quality products at the lowest prices on the market.

- 2016

By its 25th anniversary, Electromechizmerenie completed its strategic program on modernizing the production equipment. The number of clients reached 700, 19 of which were automobile plants. Our product catalog expanded beyond 200 items.

- 2019

We received two new certificates, which confirmed our compliance with ISO 9001:2015 + IATF 16949:2016. We also started shipping products to ‘ABER’, a manufacturing plant located in Portugal. These achievements perfectly marked the team’s continuous commitment to improving quality management standards.

- 2021

Our company turned 30 on March 28! Shortly before the birthday, we shipped the first batch of the new sensor model 6022.3829-02. This product became the 267th item in our product catalog.

- As of today, EMI is an important player on the market for automotive components in Russia, thanks to many years of hard work and to a constant desire to move forward. Our team continues to master the manufacturing of new items as well as to polish the quality of production and to optimize its costs. We are pleased to see a high demand on our work and to realize that we make a positive impact on the lives of millions of people.